Can I Use A Syringe Filter Multiple Times Researchgate

First published at see.leeds.air-conditioning.uk on 30th October 2015. Updated 10th November 2017 past Andy Connelly

Introduction

Syringe filters are more often than not used to remove particles from a liquid sample prior to some kind of analysis to avoid harm to equipment (eastward.m. ion chromatography, ICP, etc.) They are relatively affordable, tin can be used for small volumes, and avoid the difficulties involved using Buckner filter set ups or like.

The main two are types of filters are either those where you can recover your sample or not. The majority of syringe filters used do not allow you to repossess the solid. They are often used earlier analysis to remove any solid, undissolved, material. Other, filter holder (in-line) types allow you to regain your filter (Figure one).

Syringe filters normally use membrane type filters which have a specific particle size cut off (e.g. 0.45 μm). Syringe filters are also bachelor for the filtration of gases and for the removal of bacteria from a sample. They are also used in illicit drug harm reduction (although not in the lab please!) [1]

The questions I enquire here are:

- Which syringe filter is right for you?

- Are syringe filters really as inert as y'all recollect?

- What is the best method of using a syringe filter?

Effigy 1a: Syringe filter.

Figure 1b: In-line filter.

Pore size

Filters come up in a variety of pore sizes. The most common ones used in concrete chemical science laboratories are 0.ii um and 0.45um. Generally, 0.45um is sufficient for the bulk of procedures. However, where smaller particles may be present in the sample 0.2 um or 0.1 um might exist more advisable. If you need to filter a smaller particle size (for example, to remove colloids) other types of filtration may be more appropriate; for instance centrifugal filters.

* components passing through 0.45μm filter are oftentimes accounted to exist "dissolved" or "soluble" This in an operational definition and, while practical, is arbitrary and inaccurate as colloids and polymers tin can penetrate through the filter together with truly dissolved substances. [3]

Filter material

At that place are many different filter materials used in syringe filters. Some of the almost mutual are cellulose acetate (CA) and polyethersulfone (Human foot). The key differences are chemic compatibility, catamenia rate, and outburst pressure (i.due east. force). The material will also requite variation in the effective filtration expanse (EFA) and therefore the chapters of the filter.

A pick of the main options are [iv,5]:

- Cellulose Acetate (CA): Excellent flow rates. Very low protein binding, so they are suitable for protein recovery applications. Hydrophilic, so fine for aqueous and alcoholic media although they have limited solvent resistance. pH range ~4-8.

- Cellulose nitrate: High mechanical strength, loftier flow rates, and low extractable levels. A good pick for trace chemical element assay applications. High protein binding. pH range ~4-8.

- Regenerated cellulose (RC): made from pure cellulose without wetting agents. Chemical resistance to a broad variety of solvents. High moisture force. Hydrophilic, and then suitable for aqueous and organic samples. Very depression protein binding chapters. pH range ~three-12.

- Glass Microfibre (GMF): chemically inert and bachelor in higher pore sizes than other membranes. Mechanically extremely stiff and tolerant to organic solvents. Not idea with strong acids (particularly hydrofluoric acid) or bases. Ideal for high particulates solutions, often used as a pre-filter before a membrane filter. Not a membrane filter and so has a slightly less verbal retention efficiency than membranes. Will contribute extractables that interfere with ionic and metals analysis.

- Nylon: Nylon membrane filters are hydrophilic, flexible, tear-resistant, and autoclavable. They are resistant to a range of organic solvents and suitable for use with loftier pH samples. Nylon binds proteins. Unsuitable for acidic solutions. pH range ~3-14.

- Polyethersulfone (Human foot): Hydrophilic, stable in depression pH, have low levels of extractables, and exhibit low protein binding, making them suitable for many aqueous and organic solvents. Foot membranes permit higher liquid menstruation than PTFE. Temperature resistant. pH range ~3-fourteen (sometimes quoted as one-14).

- Polypropylene (PP): slightly hydrophobic, can be used with a very wide range of solvents including aggressive difficult-to-filter solutions such as strongly acidic samples. High and uniform tolerance to heat and mechanical stress. pH range ~ane-fourteen.

- Polyvinylidene difluoride (PVDF): designed for high tensile forcefulness, loftier solvent resistance, and low poly peptide binding, making them suitable for biomedical filtration, sterilization filtration, and HPLC sample preparation. pH range ~1-xiv.

- PTFE: is perfect for the filtration of gaseous or organic solvent-based samples and highly corrosive substances. Hydrophobic so provides chemic resistance to aggressive media and splendid temperature stability assuasive an extended sampling range. If used with aqueous samples, the membrane usually requires pre-wetting (normally by using a small-scale amount of booze). Tin can as well be used to preclude wet passing through air vents. pH range ~1-14.

Filter size

The diameter of the syringe filter is a skillful indication of the EFA and the hold-up volume. As particles are removed from the fluid, they block pores of the syringe filter and reduce the usable portion of the filter eventually causing the filter to cake upwardly. Particulate-laden fluids generally plug a filter more rapidly than "clean" fluids. Increasing the size of the filter (and/or the EFA) allows dirtier samples to be filtered. If the pressure required to push liquid through the filter becomes very high it is likely blocked and needs replacing. If you lot button too hard yous may harm the filter then let particles through.

The larger the diameter of the filter will also increase the hold-upwards volume. This is the volume of liquid remaining in the filter subsequently use. A filter with a low hold-up volume is recommended for use with expensive fluids or those with limited availability.

The table beneath outlines full general guidelines to the appropriate filter size for different volumes of fluid.

Introduction

Contamination of your sample by syringe filters is an consequence that is non commonly discussed. To find out the effect we ran some experiments looking at how much contamination we received on passing Type I deionised water and 2% nitric acid through a syringe filter.

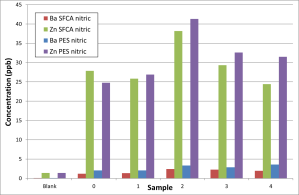

Showtime we drew 10ml of solution into the syringe and expelled into a labelled tube (no filter); this was sample 0. Then the same solution was drawn into the syringe then expelled through a syringe filter; this is sample one. The filter was removed, the media drawn upwards once more, the filter replaced, and the sample delivered into some other tube. This is sample 2. This process was repeated to produce a sample 3 and sample iv.

The solutions were then analysed in-house using ICP-MS for the post-obit elements (Li, Na, Mg, Al, M, Ca, 5, Cr, Mn, Fe, Co, Ni, Cu, Zn, Every bit, Rb, Sr, Cd, Cs, Ba, Atomic number 82, and U).

Results and discussion

The full set of results can be found in this file Filter_rinse_tests. We only carried out a very limited number of tests so the results are only a guide. More work is required to ostend the discussion below.

When rinsing with h2o, for some elements, such as Na and Ca, the first rinse contaminated the solutions with impurities in the ppb range (Effigy 2 and 3). After that the levels dropped significantly. However, for other elements, such equally Ba and Zn, the syringe introduces meaning contamination (Effigy 3). These elements then seem to "stick" to the syringe filter, but being released on later flushes.

When rinsing with 1% nitric, for some elements, such as Na and Ca, the first rinse contaminated the solutions with impurities in the ppb range (Figure 4 and 5). After that the levels dropped significantly back to the groundwork level. Yet, for other elements, such every bit Ba and Zn, the syringe introduces meaning contagion (Effigy 3). Once more, these elements then seem to "stick" to the syringe filter, only beingness released on later flushes.

More than piece of work is required to meet if other elements behave in this way.

Conclusion

From the piece of work washed here it is clear that the syringe filters trialed in this work were not inert. They released potential contamination at the ppb level in all situations. If such contagion is potentially an issue you may need to adapt your filtering technique appropriately – see below.

From the discussion above and the ascertainment of low level impurities in filtered solutions we suggest the following methods for using syringe filters (some of this taken from [two]). This is a suggestion merely and in no way replaces thorough trials with your ain samples. This is not a recommendation.

Basic method

This is the most basic method of using a syringe filter.

- Load the sample into the syringe.

- Attach the filter securely with a twisting motion. With a luer slip syringe, this is about i quarter turn as the filter is pushed on. If the syringe has a luer lock (equally in this case), prepare information technology firmly but do not over-tighten.

- Concord the assembled syringe and filter vertically to wet the membrane evenly. This prevents air blocks and promotes high flow rates as the sample is spread evenly over the membrane surface.

- Press the syringe plunger gently to push sample through the filter. If possible, discard the first 0.25-0.5ml of sample considering if there is any contamination present, it is probable to be higher in those kickoff few microlitres of sample. If the back pressure always increases significantly, change the filter as it may have plugged. Avert pressing excessively as this could cause the filter housing to flare-up.

- Change filter and repeat for next sample

Variations

- If you have a limited amount of sample – you can utilise the "air-purge" method to reduce the amount of sample lost in the syringe. To do this depict a modest amount of air (about 1ml) into the syringe earlier filling with the sample solution. This air is used to purge the filter at the end ensuring the minimum sample is left in the filter.

- If you lot are concerned about contamination (ppb level) – as results above show syringe filters tin produce contagion at low levels. To reduce the amount of contamination you lot should wash the filter through with ultra clean water or weak (1%) acrid solution earlier filtering your sample through same filter. The results higher up evidence that yous may have to do this multiple times to truly "clean" the filter. The wash solution tin be ejected from the filter using air purge method described in a higher place.

References and acknowledgments

[1] Sundaram, S; Auriemma, M; Howard Jr, G; Brandwein, H; Leo, F (1999). "Application of membrane filtration for removal of diminutive bioburden organisms in pharmaceutical products and processes". PDA journal of pharmaceutical scientific discipline and technology / PDA 53 (iv): 186–201. PMID 10754712.

[2] Manual_Minisart_RC_SRP_NY_PES_SL-6193-p.pdf, www.sartorius.co.uk/fileadmin/fm-dam/DDM/Lab-Products-and-Services/Lab-Filtration/Filtration-Devices/Minisart/Manuals/Manual_Minisart_RC_SRP_NY_PES_SL-6193-p.pdf, Sartorius (2015).

[3] Radojevik & Bashkin, Practical Environmental Analysis, RSC, 1999

[4] http://www.gelifesciences.com/webapp/wcs/stores/servlet/catalog/en

[5] Sartorius, Laboratory filtration products, SLU0006-e160712, 2016

Can I Use A Syringe Filter Multiple Times Researchgate,

Source: https://andyjconnelly.wordpress.com/2016/09/28/syringe-filters/

Posted by: jamesexther.blogspot.com

0 Response to "Can I Use A Syringe Filter Multiple Times Researchgate"

Post a Comment